Small Diameter Stainless Steel Tubing Fabricator

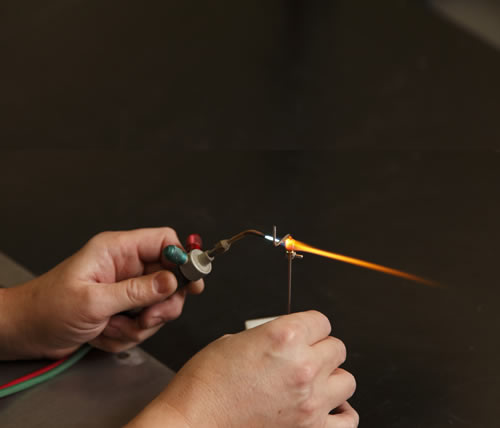

Tube Brazing

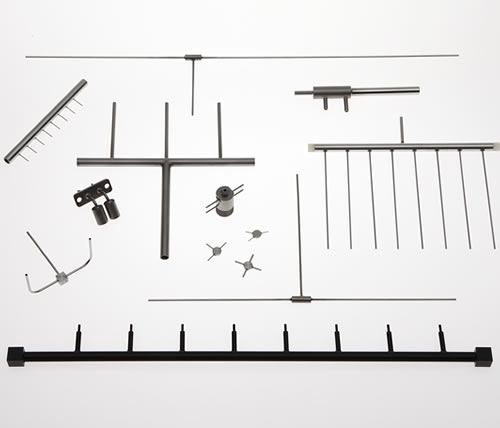

No one has more experience brazing hypodermic and other small tubing than New England Small Tube. Our expertise allows us to provide strong, clean, dependable joints with minimal sized fillets. Some examples of the complex tubing assemblies we can produce are:

- Coaxial Sampling Probes

- Enclosures

- T-Joints

- Dispensing Manifolds

- Many other possibilities

A variety of alloys are available to produce brazed joints. The most common alloys used here are silver and nickel. Each of these materials provides a strong bond. We use our expertise in helping to determine the best method to give you the maximum strength with the minimum amount of heat applied to the part.

SILVER BRAZING is performed at a relatively low temperature, far below the annealing point of stainless steel, while still allowing the brazing materials to flow easily into a joint.

NICKEL ALLOYS are highly resistant to corrosion. These brazing materials are applied at a higher temperature and are typically used for bonding heat resistant alloys.

INDUCTION BRAZING allows us to localize the annealing process and provide great repeatability of the brazed joint. Inert gas may be introduced, if needed, during the brazing operation to minimize oxidation.

FURNACE BRAZING is an excellent choice for tube manifolds, preheaters, and any other application where the entire assembly can withstand the heat of the brazing furnace. Many complex assemblies require furnace brazing.

Building a probe? Head over to our Sample & Reagent Probes page for ideas and information on building your entire assembly.

Call us today at (603)429-1600 to learn how New England Small Tube can lower your cost and save time on your application.