Small Diameter Stainless Steel Tubing Fabricator

Laser Welding and Drilling

Laser Welding and Laser Drilling

High quality and repeatable laser welding and laser drilling is readily available at New England Small Tube Corporation. We also offer Laser Marking as well.

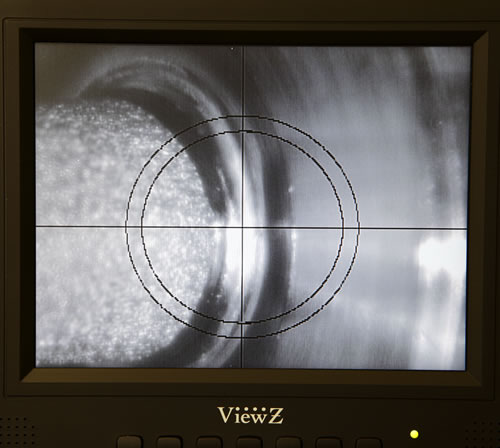

Laser welding is a strong, fast, accurate and clean way to join your assemblies without the use of filler materials, that may contaminate or change your parts. The cleaner processing means less procedures need to be completed after the weld, resulting in a faster turnaround time for prototypes and productions quantities. Part specific tooling allows for welding processes to be adapted to your application with very few limitations, giving the welder the ability to join a greater diversity of shapes and sizes.

NEST’s welding processes assure the smoothest and cleanest weld possible every time, helping to achieve the best performance of the full assembly.

Laser drilling can provide burr-free tight tolerance holes in several different shapes and sizes. The ability to program different dimensions, allows laser drilling to be an incredibly versatile way to create “thru-holes” and other “cut” features on your part.

Think laser welding or laser drilling might be the solution for your project? Please call us today, email [email protected] or submit an attachment on our Request A Quote form to discuss your project with a Sales team member.

Laser Marking

If your part needs to be permanently marked with a part number, serial number, or company logo etc., laser marking can accomplish this without discoloration, oxidation or deforming of the part.

Learn More About Laser Marking

Building a probe?

Head over to our Sample & Reagent Probespage for ideas and information on building your entire assembly.