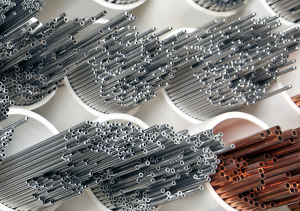

Small Diameter Stainless Steel Tubing Fabricator

Tubing Considerations

There are a few basic essentials to consider when fabricating a tubular part: the size, the material, the temper, and finally the method used to draw the tube.

For precision stainless steel tube sizes, there are two different kinds of tubing: hypodermic gauge tubing and fractional tubing.

Fractional size tubing is made to all of the common fractional sizes. When choosing a size, outside diameters (O.D.) are usually specified along with the wall thickness, rather than the inside diameter (I.D.) For example:

1/4" Outside Diameter x .035" Wall

or

1/8" Outside Diameter x .020" Wall

This is different from hypodermic gauge tubing or what is commonly referred to as needle tubing. Hypodermic tubing is typically referred to by its gauge size. Gauge sizes are determined by the outside diameter and the inside diameter of the tube.

Tubular Part Size

Please take a look at our Hypodermic Gauge Chart or Fractional Tube Chart for help with picking out the right tube. The sizes on these charts are typically readily available and in stock. Custom sizing is also available if your application requires it. Please contact us if you need help with finding the right size, or if you don’t see what you’re looking for on our charts and we can help accommodate you.

Small Tube Material Selection

While choosing the right material for an application, there are many things that need to be considered. Here at New England Small Tube, the majority of materials we work with are 300 series stainless steel, specifically type 304 and type 316. We also frequently work with copper, brass, Inconel, and titanium among other specialty alloys. Please refer to our Materials section for more information on each of these alloys. We will be happy to assist you in choosing the right material for your application.

Small Tube Temper Selection

The next consideration when choosing the proper tubing is the temper. Temper is how hard a tube is and it is measured by the tensile strength. Generally, off-the-shelf hypodermic tubing is full hard and off-the-shelf fractional tubing will be annealed (soft). Please see the chart below for reference. Temper is an important consideration if an application requires fabrication or bending.

Temper (Tensile Strength)

Note: Reference Only

- Full Hard

- Tensile Strength ≈ 170,000 PSI

- "Needle Hard"

- This is the cold worked condition of the tube after drawing

- 3/4 Hard

- Tensile Strength ≈ 140,000 PSI to 160,000 PSI

- This condition is achieved by heat treating the tube after drawing

- 1/2 Hard

- Tensile Strength ≈ 120,000 PSI to 140,000 PSI

- This condition is achieved by heat treating the tube after drawing

- Annealed

- Tensile Strength <120,000 PSI

- "Soft"

- This condition is achieved by heat treating the tube after drawing

Small Tube Draw

The last consideration when choosing a tube is how the tube was drawn or made. The three basic methods or types of tubing are seamless, welded, and welded & drawn. Seamless tubing is made by punching a hold through a billet and drawing the material to size. This method can be used to form very thin walled tubing or very thick walled tubing. Welded material starts with a flat sheet, that is rolled and welded creating a rather noticeable seam. Welded & Drawn tubing starts the same way, however, it is plug drawn after rolling. That means a plug is put through the inside of the tube to smooth out the seam. If necessary, this step can be done multiple times to produce a better finish on the internal diameter.

Call us today at (603)429-1600 to discuss your application and how New England Small Tube can help you!