Small Diameter Stainless Steel Tubing Fabricator

Guide to Design and Fabrication of Probes & Tube Assemblies

Since 1986 New England Small Tube Corporation has been helping companies fabricate Probes, Cannulae, Needles, Pipettes and other Custom Assemblies.

Customers spanning several different industries have trusted NEST’s expertise for the fabrication and completion of their probes and tube assemblies from prototyping through production.

Types of Probes Fabricated

Across many industries, probes vary based on the type of measurement or analysis needed. Common types of probes fabricated here at NEST include:

- Temperature Probes

- Blood Sampling Probes

- Chemistry Probes

- Aspiration Probes

- Reagent Probes

- Pressure Probes

- Level Sensing Probes / Conductive Probes

- Microbiological Sampling Probes

- Other Customer Probes

These probes and assemblies are required for collecting data and samples in fields such as Instrumentation, Medical Diagnostics, Environmental Monitoring, Petrochemical / Oil and Gas, Vet Diagnostics, Gene Sequencing and many more. They are essential to the measurement and analysis of chemical and physical properties and each probe and assembly serves their own specific purpose.

Sample and Reagent Probe Guide

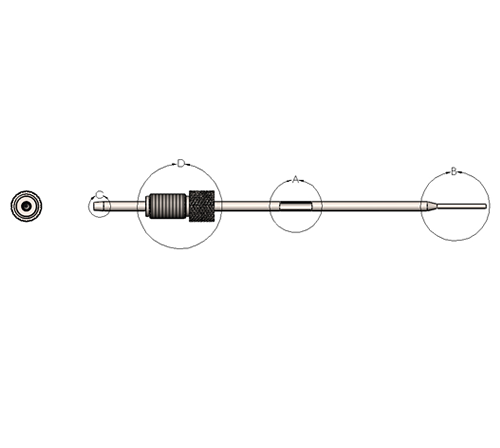

Below is a simplified guide created to help with the beginning development stage of a probe assembly and some common considerations that can help smoothen and standardize your design. Remember to keep these in mind to make your parts more cost effective and easier to obtain. The rendered image on this page is an example of a very basic probe assembly to walk you through this guide.

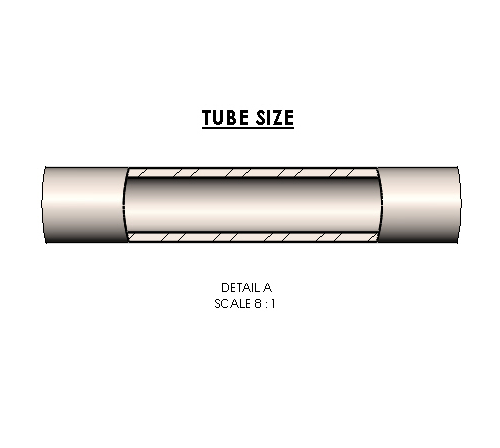

Sample & Reagent Probe Tube Selection

It all starts with the tube. Tube size, material and finish affect everything from volume to clearance to carryover. While there are several different options that might work for your particular application, some sizes, custom sizes in particular, can be harder to obtain and can increase cost and lead time. This same principal applies to the tubing material as well.

We encourage you to call or email us so that we can assist you in picking out the right tubing. By employing our extensive database, we have the ability to search through hundreds of miles of stock that includes custom sizes and materials. We can select a material and size that will be the perfect fit for your application.

Choosing a standard size or commonly used material, will ultimately improve part lead time and cost effectiveness.

Features can also be added to the tubing to enhance the performance of the part. Our Milling page can help you pick out any feature you might need for your tubing.

For help deciding on the right sizes for your application, head over to our Standard Hypodermic Tubing Chart or our Fractional Tubing Chart.

For assistance in choosing the right material, check out our Materials page for descriptions of our more commonly used materials.

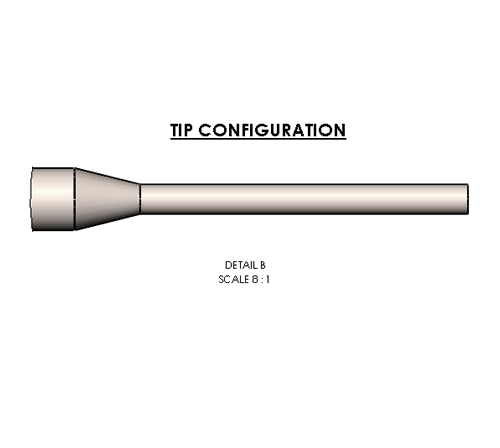

Probe Tip Configuration and Fabrication

The tip is the working end of the probe. There are numerous different styles for the tip, but like all other aspects, keeping this within a few common possibilities will help with the overall lead time and production process. Custom configurations and tips can be fabricated upon request.

Our production experts can swage, form, grind or machine a tip specific to your application that will enhance the function of your probe, needle or cannula for often better than expected results.

Visit our Swaging and Tube Grinding pages for help when considering the right tip for your application.

We are always willing to assist you during any stage of development. Give us a call today at (603) 429-1600 to discuss all of your options in more detail, including our full capabilities.

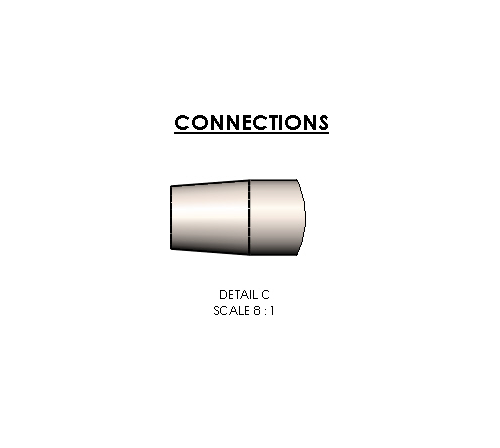

Back-End Connections for Sample & Reagent Probes

A solid connection is paramount when you are sampling, dispensing, pipetting. NEST can help during the design phase and build a probe or assembly that will connect to your system easily with no leaks. Barbs, tapers, flares, fittings and flanges are some of the connecting enhancements we can add to your probe or assembly. Choosing the right connection, is important to achieving target performance.

Specific features and custom sized connections depending on the application are always accommodated

Check out our Precision Machining page for ideas about connecting your probe assembly.

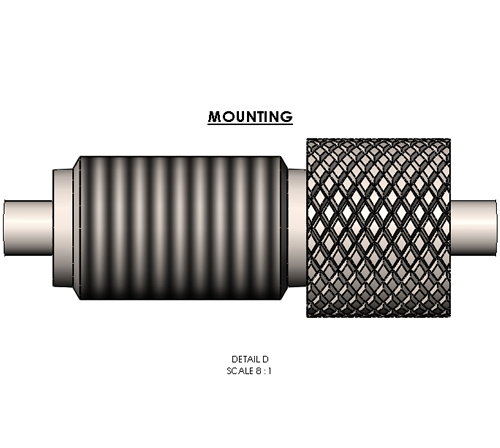

Mounting Sample & Reagent Probes to an Instrument

Securely and accurately mounting your probe or tube assembly is also vital to the function of your system. We can build mounting features directly into the design of your assembly or fabricate a multi-piece assembly.

Fittings, mounting blocks, ferrules, collars or adapters can all be built into your probe so that it can go from out of the box to fully connected in an instant.

Visit our CNC Machining page for ideas on mounting your assembly.

If a larger mounting feature is required, deciding on how to bond the multi-piece construction together will also become an important factor. This bonding can be done in several ways but the two most common at New England Small Tube are brazing and laser welding.

For information about how to connect with multi-piece construction, head over to our Laser Welding and Brazing pages.

If you couldn't find what you were looking for here, call us today at (603)429-1600 to discuss your application and how New England Small Tube can help you!