Small Diameter Stainless Steel Tubing Fabricator

Precision Tube Bending, Coiling, Forming

Specialized Tube Bending, Forming and Coiling

New England Small Tube is a trusted partner for precision tube bending in critical applications across a wide range of industries.

Our specialized services are designed to maintain structural integrity, optimize fluid dynamics, and ensure full compliance with safety and performance standards.

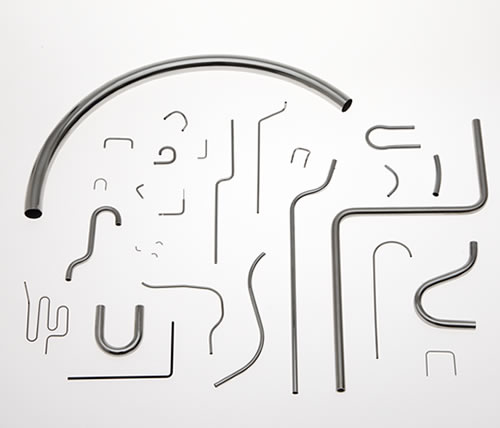

Complex Geometries & Custom Configurations

Our tube bending capabilities enable the creation of complex geometries and customized designs without the need for additional fittings or connectors. From simple 90° elbows to compound bends with multiple planes, we deliver precise, repeatable results that meet even the most demanding specifications. Achieving this level of precision requires tight control over bend radius, wall thickness, and geometric tolerances. With decades of experience bending stainless steel tubing, NEST ensures that every bend aligns perfectly with your design requirements.

Expert Tube Bending & Fabrication

Each bend is produced using custom fixtures tailored to the tube’s outside diameter and bend radius. This approach results in smooth, uniform bends with minimal distortion—critical for both performance and reliability.

Whether performed manually or through automated processes, our methods are highly repeatable, delivering clean, consistent bends in tubing sizes from .375″ OD down to .016″ OD. During the design phase, wall thickness should be carefully considered. Tubing that’s too thin or heavy may crimp or collapse depending on the bend radius. As a guideline, maintaining a bend radius greater than twice the outside diameter helps prevent these issues. Special design requirements can typically be accommodated as well.

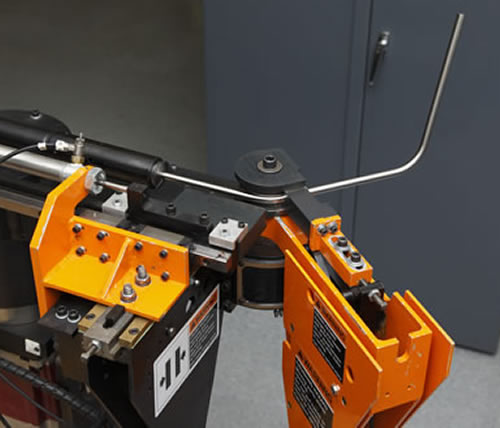

Specialized Machinery, Skill & Expertise

Bending, forming, and coiling stainless steel tubing demand specialized equipment and expert craftsmanship. Key variables—such as stainless steel grade, tube diameter, wall thickness, and bend radius—are carefully evaluated to ensure the finished product meets all performance and quality standards.

NEST’s experienced technicians follow strict industry standards, preserving the mechanical properties and surface integrity of the tubing throughout the bending and forming process.

Comprehensive Tube Forming Capabilities

Beyond bending, tube forming includes a variety of additional processes—such as flaring, swaging, expanding, and end-forming—to alter tube geometry and configuration. These techniques allow us to tailor tube shapes, diameters, and cross-sections to fit your exact application requirements.

Partner with New England Small Tube

Experience the difference: lower costs, faster lead times, and exceptional quality for all your stainless steel tubing, probes, and specialty needle requirements. Call us today at (603) 429-1600 to get started.

Tube Bending

Tube Forming