Small Diameter Stainless Steel Tubing Fabricator

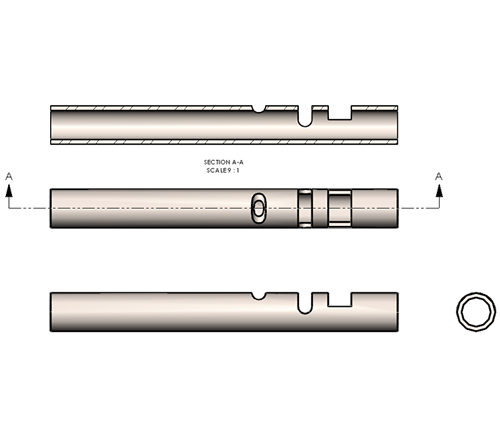

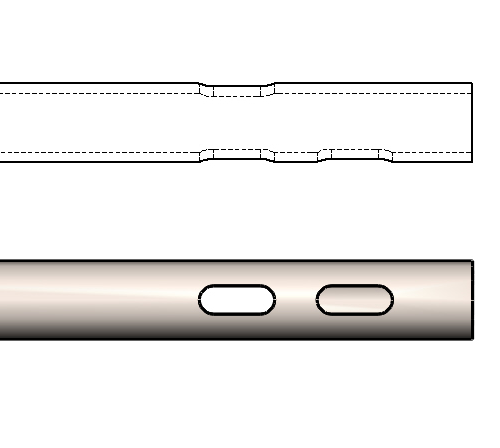

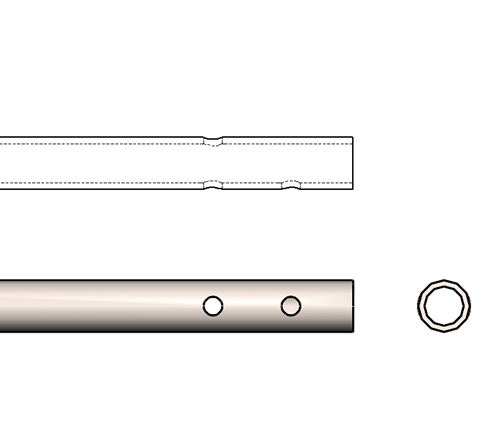

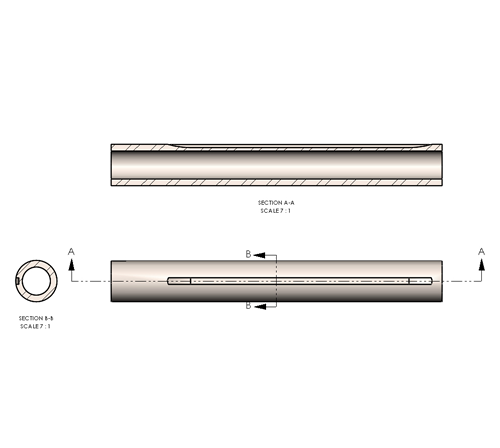

TUBE MILLING

New England Small Tube’s experience in milling and turning allows for holding tight tolerances with quick turnarounds on a consistent basis.

Tooling created in-house and specific to each project, saves time and money from prototyping to production.

Our CNC Milling and CNC Multi Axis capabilities allow New England Small Tube to make a wide variety of components to fit your tubing application.

Our tool room and CNC lathes cut cylindrical parts by indexing a cutting tool into the spinning part. Our Milling and Multi Axis machines use spinning cutters to remove material.

Our skilled machinists can cut complex components as well as round, rectangular, or hex shaped parts from a large variety metals and plastics. Special requests and projects will also be accommodated depending on your requirements.

Call us today at (603)429-1600 to learn discuss our milling and turning capabilities.

Building a probe? Head over to our Sample & Reagent Probes page for ideas and information on building your entire assembly.